Coating » Thin Film Coating

A thin film coating is a layer of material ranging from fractions of a nanometer (monolayer) to several micrometers in thickness. Electronic semiconductor devices and optical coatings are the main

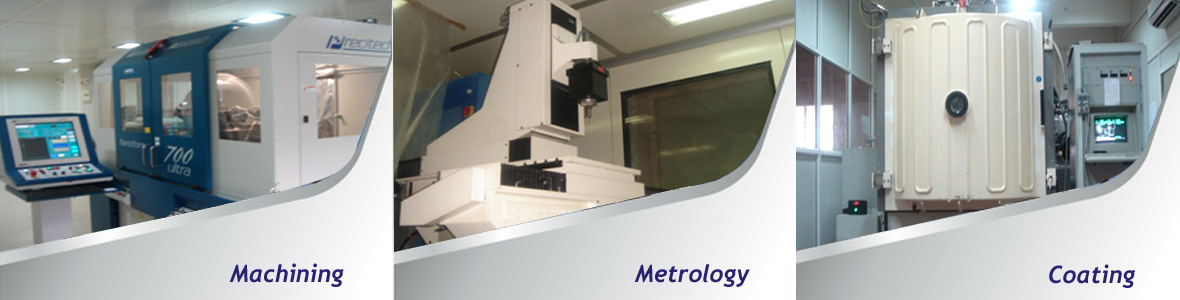

Mechvac specializes in supplying precision thin film coatings for the UV, visible and near IR spectral regions. Our coating chambers accommodate many different substrate shapes and sizes, and utilize state-of-the-art technology to produce optical coatings with excellent spectral performance, laser damage threshold, and environmental durability.

At Mechvac, we understand that process control plays a critical role in thin film deposition. We manufacture our own deposition fixtures and tooling with in-house CNC capabilities. Our coating engineers use advanced thin film design software and theoretical evaluation techniques to develop optimal coating designs. Our experienced technicians closely monitor the inherent properties of each material and layer configuration throughout deposition. Coating chamber parameters are rigorously controlled to ensure process repeatability, and coatings undergo thorough environmental and spectral analysis and testing prior to shipment.

Being vertically integrated allows Mechvac unparalleled freedom in addressing the inherent challenges of thin film deposition. In addition to supplying coating on fully in-house manufactured components we provide coating services for customer furnished

Mechvac specializes in supplying precision thin film coatings for the UV, visible and near IR spectral regions. Our coating chambers accommodate many different substrate shapes and sizes, and utilize state-of-the-art technology to produce optical coatings with excellent spectral performance, laser damage threshold, and environmental durability.

At Mechvac, we understand that process control plays a critical role in thin film deposition. We manufacture our own deposition fixtures and tooling with in-house CNC capabilities. Our coating engineers use advanced thin film design software and theoretical evaluation techniques to develop optimal coating designs. Our experienced technicians closely monitor the inherent properties of each material and layer configuration throughout deposition. Coating chamber parameters are rigorously controlled to ensure process repeatability, and coatings undergo thorough environmental and spectral analysis and testing prior to shipment.

Being vertically integrated allows Mechvac unparalleled freedom in addressing the inherent challenges of thin film deposition. In addition to supplying coating on fully in-house manufactured components we provide coating services for customer furnished